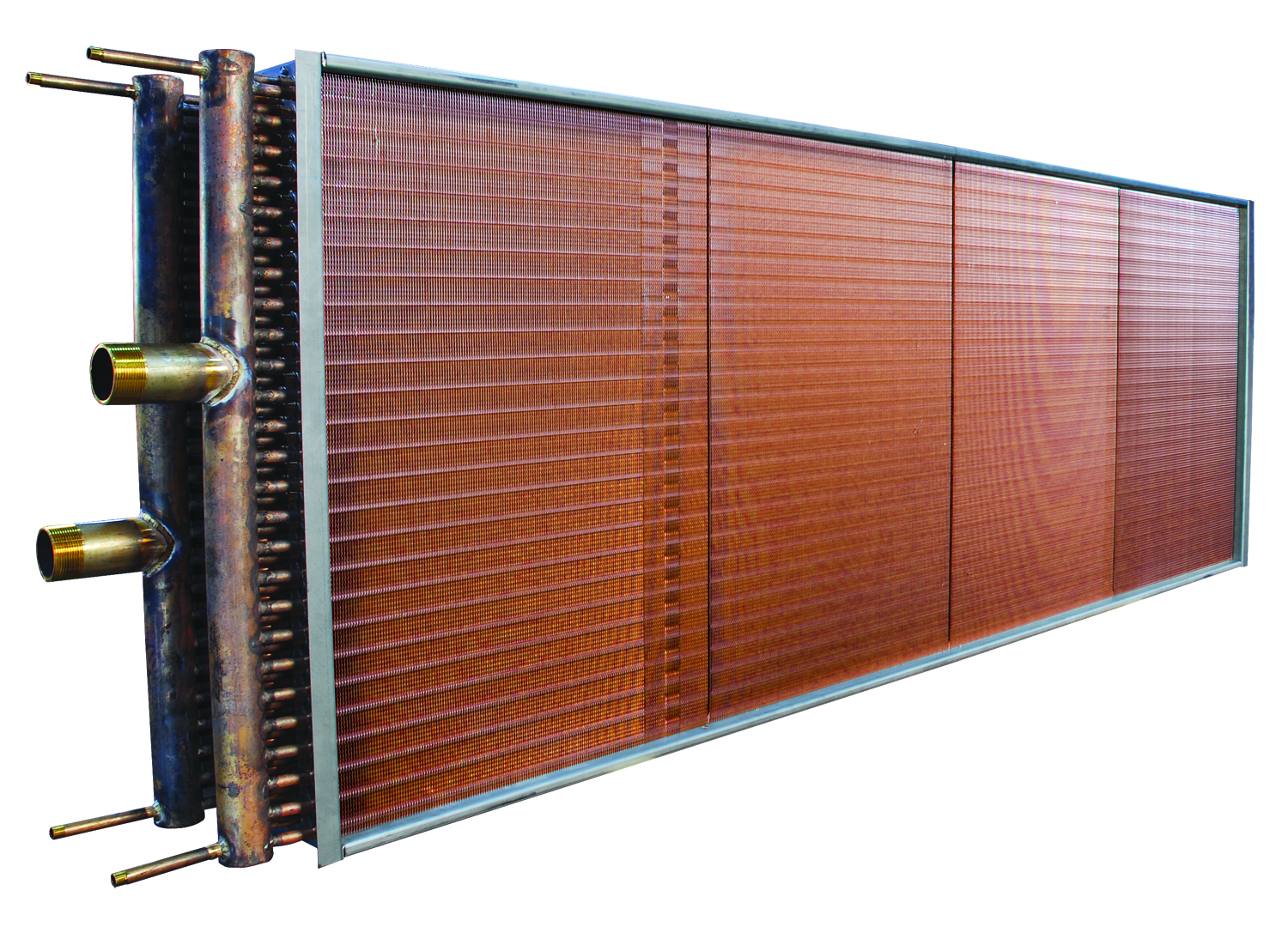

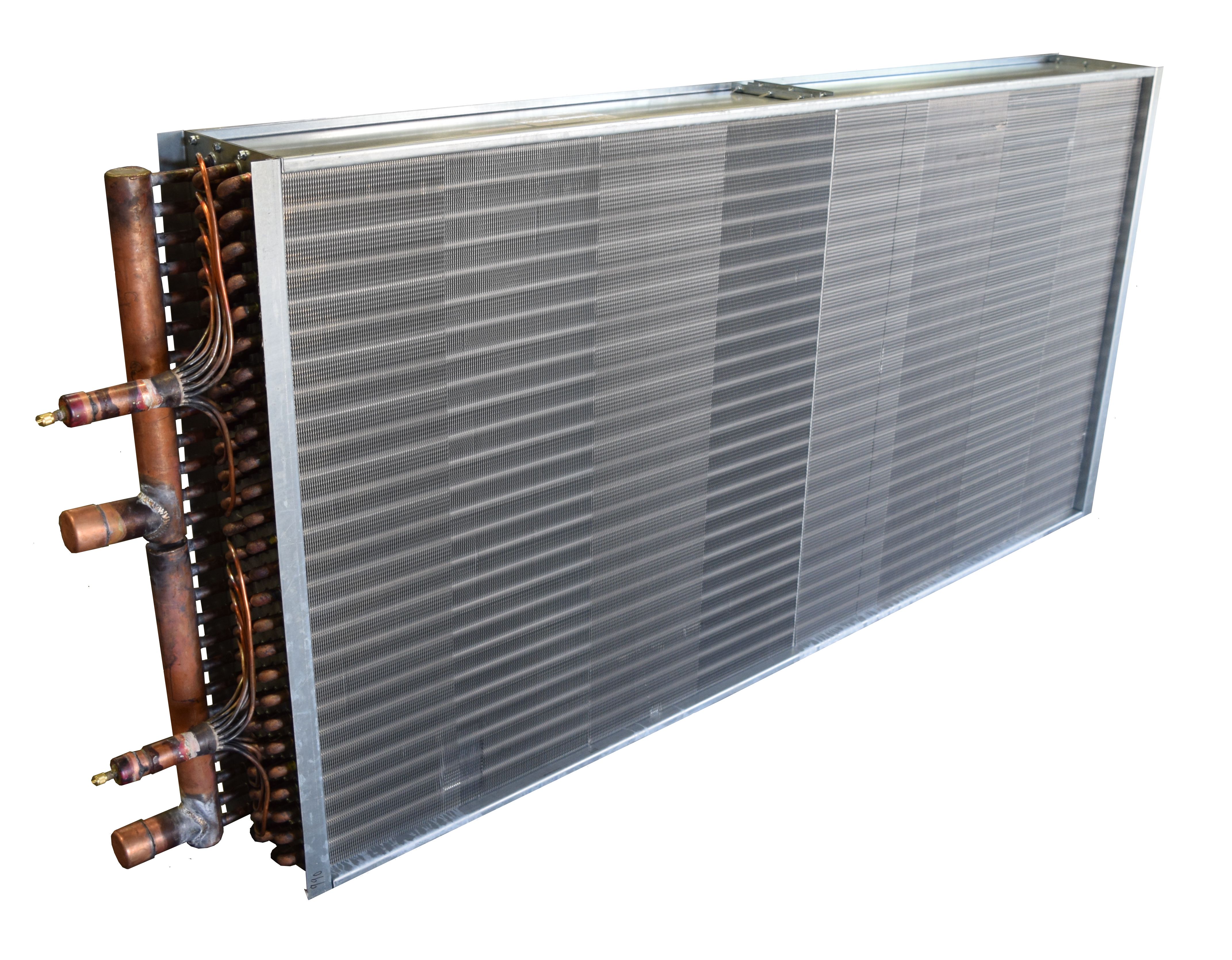

Plate Fin Construction

Plate Fin coils are used for heating, cooling and dehumidifying. In addition to water, a variety of other heating and cooling media, such as glycol and brine solutions, thermal oils, and refrigerants for DX applications, can be used.

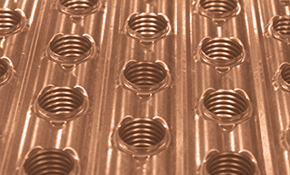

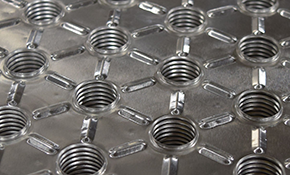

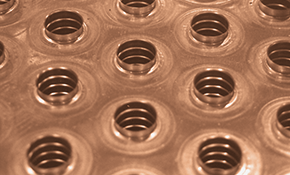

Standard Fin Designs

All Plate Fin coils feature flat or patterned plate fins of aluminum, copper, stainless steel, or carbon steel. The fins are permanently attached to the tubes by expansion of each tube. Full fin collars allow for both precise fin spacing and maximum fin-to-tube contact. Material thicknesses on the fins can range from 0.0055” to 0.016” depending on the material being used. Three standard plate fin patterns are available:

WAVE FIN

The wave fin configuration across the fin provides the maximum heat transfer rate for a given surface area, and is the standard fin configuration used.

STAR FIN

The star fin pattern corrugation around the tubes provides less air friction drop. This pattern is used when lower air friction is desired without a drastic decrease in heat transfer

FLAT FIN

The flat fin has no corrugation, which results in the lowest possible air friction drop and lowest fan horsepower demands.

Tubes

All coils feature 5/8″ OD or 1″ OD seamless copper tubes conforming to ASTM specifications. Standard 5/8″ OD tube wall thickness is 0.020” and standard 1″ OD tube wall thickness is 0.035”. Heavier wall tubing is available up to 0.065” for 5/8” tubing and 0.134” for 1” tubing depending on the material being used. Copper-nickel, aluminum, stainless steel and carbon steel are available material options.

Tube Joints

Aerofin has a variety of methods for our tube joints. All copper based tubes are brazed with certain applications such steam heating coils using silver braze. Other tube materials, such as stainless or carbon steel will require welded joints. Coils featuring removable or box style headers will feature roller-expanded tube joints. Aerofin brazers and welders are ASME qualified.

Casings

Coil casings are heavy gauge galvanized steel for high strength, durability and as a standard are double flanged for coil stacking. Stainless steel, aluminum and other casing materials are available material options. Special configurations are available such as welded casings for airtight applications.

Testing

Aerofin’s standard coil test is performed with 300 psig air under water, however some types of coils may require different testing parameters. Coils with removable headers will be tested hydrostatically to 150 psig. Higher design and test pressures are available for special applications.